Original Products

We have developed our own products so that we could make better proposals based on our track record and know-how in overhaul and retrofit business that we have accumulated over 70 years since our founding and our experience which has been keeping in grasping our customer's demands. We could propose a variety of options and create your own machine.

We have deeply involved in various machine tools and Monozukuri both in Japan and overseas, and we could produce the original products with high operability and high accuracy.

SHF08 Small Hobbing Machine

SWP Whetstone Molding Machine

SHS202 Hob Cutting Machine

Original Products Flow Until Delivery

-

Current Situation Analysis, Meeting, Estimate

-

Parts Design, Setting, Assembly

-

Operation Adjustment, Test Cutting (Trial)

-

Accuracy Inspection

-

Installation

SHF08 Small Hobbing Machine

The theme is "Challenging maximum speed and ultimate productivity."

We improve the productivity with high-speed, high-accuracy and wide range of processing sizes.

Acceleration

We have increased hob rotation speed (MAX 9,000min-1) and achived the fastest workpiece rotation in Japan at 1,500min-1.

High Accuracy

We improve the accuracy with NC tailstock and torque control for clamp pressure.

We circulate a cooling oil for countermeasure against heat generated when the spindle rotates at high speed. We minimize the thermal displacement by suppressing heat generation on the hob shaft.

We minimize the protrusion of hob head and propose an excellent rigidity.

Wide Range of Processing Sizes

We could offer the skiving processing small module up to M2. We can meet all your needs with a wide range of processing.

Spec. Table

| Maximum Distance Between Workpiece and Hob Center | 122mm | |

|---|---|---|

| Minimum Distance Between Workpiece and Hob Center | 7mm | |

| Maximum Travel Distance of Hob Head | 300mm | |

| Maximum Inclination Angle of Hob Head | ±45° | |

| Maximum Hob Shift Amount | 70mm | |

| Maximum Hob Rotation Speed (Direct Drive Specification) | (Standard) | 5,000min |

| (High Speed) |

9,000min * Option

|

|

| Maximum Rotation Speed of Work Shaft (Standard) | 600min | |

| Fast Forward Speed | Axial | 7.5m/min |

| Radial | 5m/min | |

| From Spindle End to Tailstock Spindle End |

430mm * Could be raised up to 700mm as an option |

|

| Maximum Diameter of Workpiece | 80mm | |

| Module | 0.3~2.5 | |

| Number of Teeth | 7~270 pieces | |

| Maximum Hob Diameter | 55mm | |

| Maximum Hob Length | 80mm | |

| For Carbide Hob / For Dry Cut (Full Cover + Inner Cover) / Air Nozzle (Air Blow) | ||

| Number of Shaft | Tailstock Body Stroke Specification (including 1-axis NC) | |

SWP Whetstone Molding Machine

When you order a new whetstone to a maker, it takes about 1.5 months whereas when you mold it with our machine, it takes about 50 minutes.

You could improve work efficiency and productivity.

* At the time of using a rotary dresser

It is possible to form various types of whetstones in a short period of time by using one machine.

You could form a rack tooth profile from a solid whetstone with 50 minutes, and involute tooth profile or rack tooth profile from a one-disc whetstone with 10 minutes.

In addition, when you mount a rotary dressing device, you could use it as a finish molding machine for grinders without on-machine dressing.

It shortens time by molding, realizes cost reduction and high versatility.

Target Whetstone

| Module | 0.1~10mm ※Please consult us. | |

|---|---|---|

| Number of Teeth | Up to 7-tooth | |

| Outer Diameter | Up to 400mm | |

| Whetstone Width | Up to 230mm | |

| Mounting Weight | Up to 45 kgs including Whetstone Holder | |

* You could use both threaded whetstones and single whetstones. You could also use other various whetstone shapes.

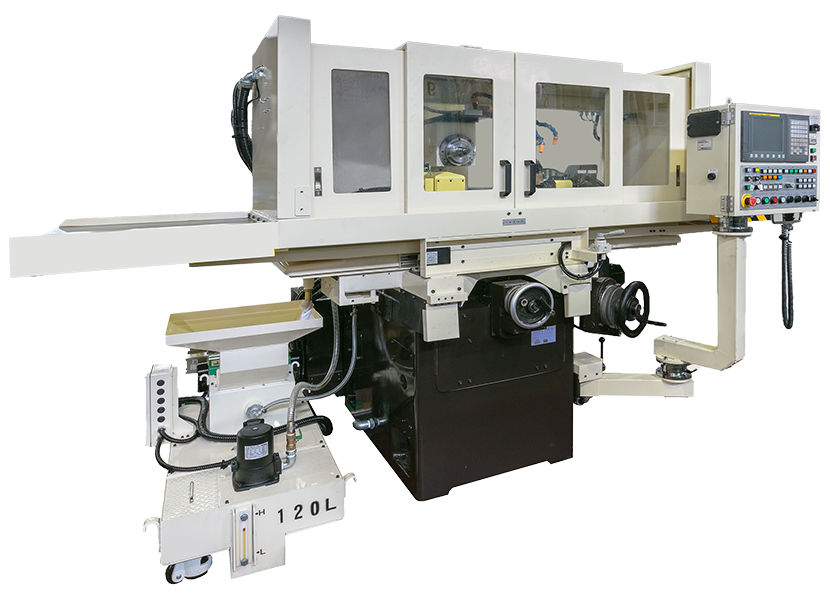

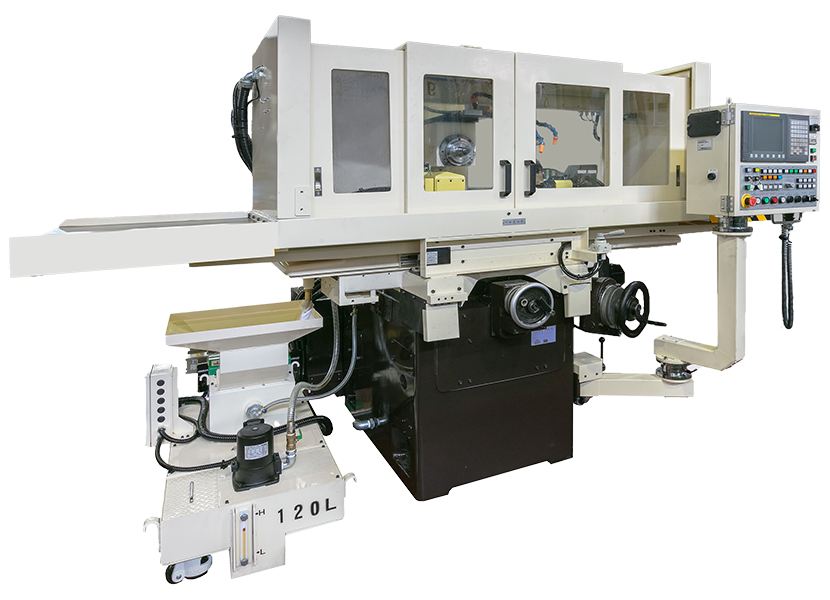

SHS202 Hobbing Machine

More compact, cheaper and easier to use.

A hobbing machine that fits any manufacturing site.

Compactness

We have succeeded compactification about 30% from the conventional models.

It could improve the work environment and work efficiency.

Cost Reduction

We have achieved approximately 25% cost-cutting compare to conventional machines.

The wet CBN creep grinding method boasts outstanding grinding accuracy (surface roughness = RmaX 1.5 μm). We have improved accuracy of cutting and extended the lifetime of hob cutters by its method.

Structure for Easy-to-use

It shortens the grinding time. (You could finish processing hob cutter with 150L, 12-gash in 17 minutes.)

Easy set-up by gearing with manual pulse handle

Operation by setting conditions with numerical input

Spec. Table

| Table Horizontal Feed Valid | Stroke | 380㎜ |

|---|---|---|

| Feed Rate | MAX8,000㎜/min | |

| Column Forward/Backward Feed | Maximum Travel Amount | 170mm |

| Whetstone Spindle Vertical Feed | Effective Stroke | 110mm |

| Whetstone Spindle | Whetstone Size (Outer Diameter) | Φ200㎜ |

| Whetstone Rotation Speed | 3,600rpm(60Hz)・3,000rpm(50Hz) | |

| Whetstone (CBN) | Φ200xΦ76.2xt15 | |

| Whetstone Spindle Motor | 3.7kw 2P | |

| Indexing Board | CNC180LFA | |

| Work Maximum Loading Weight | 50 kgs (including Arbor) | |

| Machine Weight | about 2,500 kgs | |

| Floor Area (Length x Depth x Height) | 3020x2182x2120mm | |

| Total Power | 9.5kVA | |